What does Ready Mix Concrete AccFlex ERP Solution offer?

Ready Mix Concrete AccFlex ERP Solution, of AccFlex ERP Accounting Software, is the best accounting software for ready-mix concrete activity management, Ready Mix Concrete AccFlex ERP Solution covers all ready-mix concrete production stages, starting from the procurement of raw materials going through the production stages, and ending with the delivery and sale of the finished product, and calculating profit and loss, it provides a full cycle for ready-mix concrete activity management, including all manufacturing activities, financial accounting, as well as it is characterized by a high degree of flexibility that provides you to customize the accounting software to suit the ready-mix concrete batching plants and block plants.

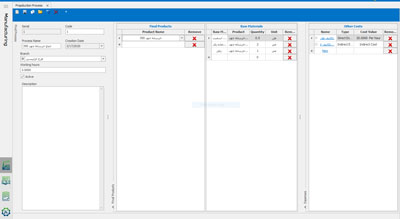

Best Ready-Mix Concrete Batching Plants Software of AccFlex ERP Accounting Software provides you the ability to create an infinite number of finished products (concrete compressive strength 200 kg/cm2- concrete compressive strength 250 kg/cm2- concrete compressive strength 300 kg/cm2) and entering components for each finished product by the items and quantities of the raw material used in its production, as well as determine the cost of each of them.

Watch Ready Mix Concrete AccFlex ERP Solution Cycle

If you looking for the Best Ready-Mix Concrete Batching Plants Software, now AccFlex ERP System provides you with an integrated set of accounting and management software specially designed in ready- mix concrete batching plants management and concrete block, has been successfully implemented in the leading ready-mix concrete companies that provide you with complete control of the company's internal departments and multi-functional concrete batching plant through a centralized, interconnected system that includes warehousing, purchasing, production and sales activities, and human resources management in addition to drivers and production equipment management.

Learn more about Best-Integrated Accounting Software for Enterprises and Companies Management

The most important characteristics of Ready Mix Concrete AccFlex ERP Solution

In light of our experience in dealing with the ready-mix concrete activity and our conduct of market research, we have designed our vision in designing accounting software that covers at least 95% of your activity needs in the various aspects of the activity that has been formulated in 10 key areas within Ready Mix Concrete AccFlex ERP Solution:

-The ability to deal with an infinite number of ready-mix concrete batching plants and link them to a centralized system and work (with the possibility of creating a database for each separate batching plant and linking it to a centralized database to overcome the problems of the internet outage).

- Production Planning processes based on the customer's pre-orders where the customer's reservation data are recorded by the date and time, the required concrete mix codes, and the delivery location, the system automatically schedules the daily and weekly production to determine your materials requirements planning process of raw materials and equipment (contracting and reservation management).

- The delivery of the customer's requests on certain phases of delivery under a concrete delivery voucher signed by the customer (production management - movement).

- Customer invoicing based on the sum of the previously issued and received receipt vouchers by the customer (general ledger management).

- Tracking of customer contracting in terms of contracted quantity, quantity delivered, and quantity rejected and remaining for the customer.

- Profitability analysis of customer sub-projects in case of multiple locations and single customer projects.

- An integrated costing system that ultimately enables you to know the costs of production orders and work orders of raw materials, labor, and manufacturing overhead.

- An integrated warehouse system that includes the purchase-to-pay cycle and internal receipts and transferring them to production.

- Notifications system enables you to get activity information on time such as customer balances, account statements, production, and delivery planning through email and SMS.

Design your work cycle on the strongest Ready-Mix Concrete AccFlex ERP Solution

Contracting and Reservation Management

Customer contracting and reservations are recorded on the system by the sales department in preparation for the operation process such as:

- Customer's name and number.

- Delivery Date & Time.

- Type and code the required mixture (content and concrete compressive strength).

- The location of the customer whose delivery is requested.

- Required equipment (pumps).

Managing production processes at the concrete batching plant

Based on the reservations and contracting of customers and previously recorded from the sales department on the system, production processes are scheduled automatically through Ready Mix Concrete AccFlex ERP Solution, and production managers review the daily and weekly operational planning and start production processes or generate the materials requirements planning in the case of raw materials shortage at the batching plant and work orders are registered on the system through the following phases:

- Recalling the work order from contracting or pre-booking to show the required quantities and technical specifications.

- The date of the work order and the equipment used is recorded.

- The availability of raw materials quantities for operation is checked, and if available, raw materials will be withdrawn for operation "actual quantities".

- Actual quantities produced and wasted shall be registered if any, and the number of operating hours for the work order shall be determined.

Delivery Management

Deliveries are registered after the completion of the production process with the possibility of registering the customer’s refusal (for quantities wasted to be registered at a later phase) and the driver responsible for delivery is registered to produce reports on the drivers’ performance.

General Ledger Management

In all phases of the work cycle on the system, General Ledger Software automatically translates all transactions with a financial impact into financial transactions into coded journal entries (Every journal entry has a unique number) that are done automatically, such as the journal entry of withdrawal of raw materials and the journal entry of adding the finished product, etc. Hence, the result of the company's actions can be known in an instant and continuous way.

At the end of the deliveries for customers, the finance department issues invoices to the customer based on the approved receipt vouchers, and the contract status can be monitored through reports.

General Ready Mix Concrete AccFlex ERP Solution Features

AccFlex ERP Accounting Software offers a set of specialized systems in the concrete activity and the framework of our experiences with the largest ready-mix concrete companies and our accurate conduct of market research, an integrated software solution has been designed that serves the ready-mix concrete activity managerially and accounting, and the solution provides the following general features:

Coding Ready-Mix Concrete Batching Plants

By AccFlex ERP Accounting Software to manage ready-mix concrete batching plants, the company activity can be managed and divided into a group of sectors according to the size of the company (the concrete sector, the block sector, the asphalt sector ...) and concrete branches and batching plants on a centralized database that includes multiple branches and within the framework of an authorization system of data on a tight basis that guarantees the work of branches are flexible and in light of the specialties addressed to each user.

The multi-branch feature provides the feature of producing analytical data and final accounts at the level of each sector and branch of a ready-mix concrete batching plant separately or grouped at the level of all branches.

Linking Batching Plants to a Centralized Database

Ready Mix Concrete AccFlex ERP Solution works with more than an application interface, the system interface can be used through the web-based system browser, the system interface can also be used through desktop-based system computers, and the two interfaces can be used at the same time. AccFlex ERP Accounting Software supports all the automation for linking between branches and batching plants, so the linking automation can be used in traditional or AccFlex ERP Systems, characterized by one of the following automation:

- Using "local server" and linking batching plants using internet connection tools.

- You can also host the database using the cloud server, and log into to the system from anywhere and at any time.

- You can also use the characterized AccFlex ERP System that enables you to work in cases of internet instability where an independent sub-database can be used for each batching plant to achieve stability in the work on the system without the need for an internet or linking to the main center, and in the case of the internet availability all data is collected on a centralized database in the main department enables them to fully assume and control each branch.

Integrated warehouse system

AccFlex ERP System supports dealing with an infinite number of centralized and subsidiary warehouses, with each warehouse linked to the branch and its items, with full support for a warehouse management system, various warehouse movements, and warehouse transfers.

Standard and Actual Cost System

Best Ready-Mix Concrete Batching Plants Management Software provides an integrated costing system that enables you to easily analyze and know the costs of the activity at all levels so that the costs of the executed work orders and the level of each item within the work order can be known from all elements of costs of raw materials, labor, and manufacturing overhead.

The costing system is not limited to determining the costs of the concrete produced, but the user can set a standard cost system that is appropriate for each concrete batching plant separately so that standards can be set for concrete manufacturing in terms of raw materials and other costs, which is useful in analyzing cost variances and knowing the causes.

Advanced Notifications System

One of the most important features available in Ready Mix Concrete AccFlex ERP Solution is the availability of an integrated notifications system that enables the user to obtain the necessary data and information promptly through e-mail and phone messages such as customer account statements, treasury balances, and banks, and messages can be sent to customers automatically with debt arrears, quotations, etc.

Ready Mix Concrete AccFlex ERP Solution Reports

Ready Mix Concrete AccFlex ERP Solution provides a unique set of reports that provide the production department, all departments of the company, and the senior management with all information about the work orders, contracts, and the operational process to help the company monitor, oversight, and decision making, these reports can be exported in more than one format from the software (Word- Excel- PDF....), the reports can also be redesigned as desired by each user, of these reports

1- Cost Variance Analysis Report

One of the most important reports that help the department to know the cost variance is it displays the standard costs of (direct material- direct labor- manufacturing overhead) and compared them with the actual costs incurred for the ready-mix concrete production and know the difference between the costs (variance), whether it is, positive variance (cost savings) or negative variance (the actual costs have increased), to analyze the causes of these variances and treat them to produce the product at the lowest possible cost and then achieve the maximum possible profit.

2- Raw Material Consumption Report

The Raw Material Consumption report displays the quantities that were issued from the raw materials warehouse for production orders so that the company can inventory control and estimates the quantities it needs for the production process so that the workflow is not interrupted and this report can be displayed during (day- month- a specific period) or for a specific item or item group.

3- Completed Work Orders Report

The Finished Product Summary report displays the quantities that are produced of the ready-mix concrete and added to the finished product warehouse during a specific period, which helps in following up the production process and the workflow quality, this report can be displayed during (day-month- a specific period) or for a specific finished product.

4- Contract Status Report

One of the unique reports from which the contract status for a specific customer can be displayed is (Draft- Terminated), knowing the quantities of ready-mix concrete that have been implemented from the contract, and also can display all contract details (Prices- Delivery Date- Delivery Period- Contract Number- Customer- Total Cost) which helps the company to monitor and complete the contract.

5- Open Work Orders Report

When implementing the production process, the quantities are withdrawn from the raw materials warehouse and added to the finished product warehouse (ready-mix concrete) an error may occur during production, and the quantities are withdrawn from the raw material warehouse without adding them to the finished product warehouse, which may cause a problem in the production process but through the Open Work Orders Report, all incomplete manufacturing process can be displayed and then can be completed again.

6- Work Orders Report

The Work Order report displays all the details of the work processes of a specific production order (Ready-mix concrete products implemented during the work order- quantity- unit- quantities withdrawn from the raw material warehouse- quantities added to the ready-mix concrete warehouse- transaction code- date- transaction serial...).

Are you looking for the Best Ready-Mix Concrete Batching Plants Software?

If you are looking for the Best Ready-Mix Concrete Batching Plants Software, AccFlex ERP System provides you Ready Mix Concrete AccFlex ERP Solution for ready-mix concrete activity management, also covers all ready-mix concrete production stages, starting from the procurement of raw materials going through the production stages, and ending with the delivery and sale of the finished product, and calculating profit and loss.

What are the Top Benefits of Ready Mix Concrete AccFlex ERP Solution?

Ready Mix Concrete AccFlex ERP Solution is characterized by the ability to create an infinite number of finished products (concrete compressive strength 200 kg/cm2- concrete compressive strength 250 kg/cm2- concrete compressive strength 300 kg/cm2) and enter the components for each finished product by the items and quantities of the raw material used in its production, as well as determine the cost of each of them.

What are the Phases of Work on Ready Mix Concrete AccFlex ERP Solution?

AccFlex ERP System provides a group of systems specialized in concrete activity. In our experiences with the largest ready-mix concrete companies and our accurate market research, an integrated software system has been built to serve the concrete activity managerially and accounting and the company's activity can be managed and divided into a group of sectors depending on the size of the company (concrete, block, asphalt...) and the branches and concrete batching plants on a centralized database that includes multiple branches and in the framework of a tightness authorization system on data that ensures creating the branches flexibly and in light of the specialties assigned to each user.

What is the document cycle in Ready Mix Concrete Software?

The ready-mix concrete batching plant documents cycle varies according to the activity size, the workflow cycle, and the volume of employment, the inventory documents cycle can start, for example with a materials receipt note received from the suppliers, then transfer the aggregate of the receipt note to a purchase invoice, as well as the sales cycle, the customer is delivered under the delivery notes and then converted to a grouped invoice.